Business task

This project, developed in collaboration with a fellow industrial engineering student, focused on designing a predictive inventory management system for spare parts within a complex supply chain environment. The goal was to address low product availability, high inventory holding costs, and reliance on costly emergency orders by applying advanced data analytics to support smarter planning and purchasing decisions.

Data sources used

The system was based on structured datasets typically found in spare parts operations, including:

- SKU-level historical demand (3-year period)

- Inventory turnover and rotation indicators

- Cost breakdowns for standard vs. emergency logistics

- Lead time records by sourcing method

- Records of expert adjustments to system-generated orders

All data was anonymized and used solely for academic and methodological purposes.

Tools used

For this project, I used Microsoft Excel and VBA.

Manipulation of data

To enable a robust analytics foundation, the data was prepared through:

- Profiling SKUs by criticality, value, sales, and rotation frequency

- Classifying items with multi-criteria techniques (e.g., ABC-VED hybrid)

- Smoothing demand signals with methods like weighted moving averages

- Using Croston-based models for intermittent demand

- Analyzing overrides of system recommendations to detect bias or inefficiencies

Analysis

We designed and tested a modular forecasting and inventory planning system that included:

- Demand Forecasting Modules

- Regular SKUs: Holt-Winters and Croston variants

- New SKUs: fuzzy logic rules to infer likely demand ranges

- Inventory Policy Module

- Fill rate optimization based on inventory cost tradeoffs

- Simulation of multiple service level targets

- Order Quantity Engineering

- Adjusted EOQ models for intermittent-demand SKUs

- System Evaluation & Simulation

- Measured fill rate, inventory cost, and logistics method impact

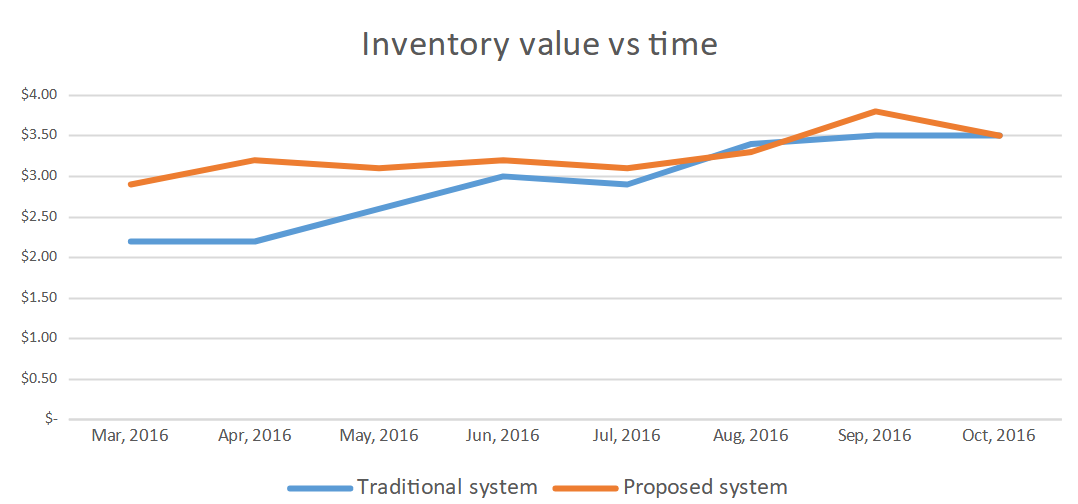

- Compared historical performance vs. model simulation outputs

Key results from the simulation:

- Improved fill rate by over 14%

- Significant reduction in emergency procurement needs

- Lower inventory policy cost relative to sales

- Quantified financial gains using improved forecasting accuracy and order planning

Further exploration

Potential directions for further development:

- Incorporating real-time demand sensing

- Supplier lead time variability modeling

- Reinforcement learning to improve order policy tuning

- Integration into a web-based analytics dashboard for decision support

Insights

- Hybrid forecasting methods significantly outperformed traditional models in environments with high SKU variability and intermittent demand.

- Manual overrides of system suggestions, though well-intentioned, often contributed to inefficiencies—underscoring the value of data-driven decision support.

- Predictive analytics can be a powerful tool in aligning service goals with cost efficiency in spare parts logistics.